While we may complain of sweltering summer days of ninety degree temperatures, relief is readily available in our air conditioned homes or businesses and shopping centers. We suffer through traffic delays in our air conditioned cars, and even if we are out-of-doors relaxing in a shaded spot, a refreshing iced drink — tea, lemonade, or water — makes the heat tolerable. Ah, the pleasures of simple creature comforts.

Not so long ago many of us marveled at the automatic ice makers in our refrigerators — gone were the days of filling trays at the kitchen tap and gingerly carrying them, without sloshing too much water, to the narrow freezer in the fridge. Wow! The convenience of making ice in your own home!

An ice cube, let alone a bag of ice, was not so easy to come by a century ago. Along South Ritter Avenue abutting the CSX Railroad stands a complex of buildings that includes one with a red brick tower — the old Irvington Ice Company. The idea for an ice factory to serve the Irvington community came about in the summer of 1913 when a neighborhood baby was seriously ill and his “life depended upon a supply of ice which was not easily available.” Friends stepped in to help the family, and a sufficient supply of the life-saving coolant saw the baby through “those sultry days and nights of watchfulness.” After the baby’s recovery, several Irvington business men decided that the only way to be free of the “manipulations and the whims of the big ice dealers” in Indianapolis was for Irvington to have its own source of ice. The Irvington Ice Company was formed with Butler College president Thomas Carr Howe as the company’s president. The other company officers were George M. Cornelius, vice president; Robert F. Davidson, secretary; Frank B. Davenport, treasurer and manager. The board of directors was composed of the officers and Dennis H. Jenkins, Guy K. Jefferies, and Perry H. Clifford.

On February 20, 1914, an article in The Indianapolis News announced plans for the construction of an ice factory in Irvington, and two months later a building permit was issued. The estimated cost for the building was $8,000 (2015: $191,044). Indianapolis engineering firm McMeans & Tripp designed the ice plant and local contractors Wolf & Ewing did the actual construction. With the installation of equipment and other development costs, the total investment in the plant was about $37,500 (2015: $895,520).

The Irvington Ice Company solved the community’s need for a dependable supply of ice at a reasonable price to insure perishable foodstuffs could be kept in the home at a time when refrigeration was not available. The ice factory was designed to meet this need for the residents and merchants of Irvington and others east of the Belt Railroad. By drawing from its own deep well for pure water, the plant could manufacture 37½ tons of ice daily and had a storage capacity of 225 tons. Initially, ice delivery was by horse drawn wagons. Customers were charged 30 cents (2015: $7.16) a hundred weight compared to the 35 cents (2015: $8.36) people in other parts of the city were paying the “ice barons.” Once again Irvington “demonstrated that it depends largely on itself to solve its own problems.”

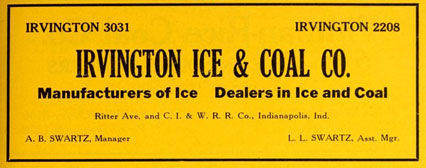

Albert B. Swartz, who had been the treasurer and manager of the company, became its sole owner around 1920, and with the addition of coal to the inventory, the name was changed to Irvington Ice & Coal Company. The increasing popularity of mass produced home appliances allowed the company to begin offering refrigerators to its customers by the end of the decade. In 1927 Rodney C. “Tompy” Thompson began his career with the company as a wagon delivery driver. He would eventually become part of the management team and a co-owner.

Albert Swartz died in 1932, and the Irvington Ice & Coal Co remained in the Swartz family with his son Leonard L. Swartz becoming president-treasurer. With the addition of motorized trucks, ice and coal deliveries became more efficient.

By the early ‘50s, the Irvington Ice & Coal Co leadership changed with E. Ellsworth Boyce becoming president and “Tompy” Thompson as secretary-treasurer. A new product was also offered by 1955 — home heating oil, and the company name once again would change to reflect this new energy source — Irvington Coal & Oil Co. Home heating tastes continued to change during the 1960s, and by the time Rodney C. “Tompy” Thompson became president and manager of the company in 1969, this venerable Irvington firm had entered its final year. Stuck’s Best Coal & Oil Company occupied the buildings for a short time before the site served a completely different purpose. For more than thirty years — into the new millennium — Custom Models, Inc., sheet metal fabricators, worked out of the old Irvington ice house.

Today the venerable Irvington Ice Company buildings are being cleaned-up and with plans to create a multi-purpose community gathering place.